Page 180 - Hojnik, Jana. 2017. In Persuit of Eco-innovation. Drivers and Consequences of Eco-innovation at Firm Level. Koper: University of Primorska Press

P. 180

In Pursuit of Eco-innovation

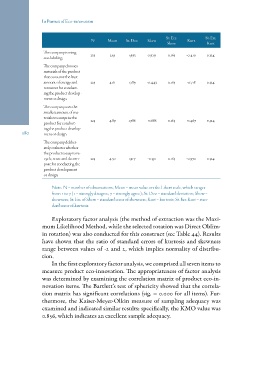

N Mean St. Dev. Skew St. Err. Kurt St. Err.

Skew Kurt

The company is using 223 2.59 1.993 0.979 0.163 -0.410 0.324

eco-labeling.

The company chooses 223 4.61 1.789 -0.443 0.163 -0.718 0.324

materials of the product

that consume the least

amount of energy and

resources for conduct-

ing the product develop-

ment or design.

The company uses the

smallest amount of ma-

terials to comprise the 223 4.89 1.786 -0.686 0.163 -0.467 0.324

product for conduct-

180 ing the product develop-

ment or design.

The company deliber- 223 4.50 1.917 -0.391 0.163 -0.972 0.324

ately evaluates whether

the product is easy to re-

cycle, reuse and decom-

pose for conducting the

product development

or design.

Note: N = number of observations; Mean = mean value on the Likert scale, which ranges

from 1 to 7 (1 = strongly disagree, 7 = strongly agree); St. Dev. = standard deviation; Skew =

skewness; St. Err. of Skew = standard error of skewness; Kurt = kurtosis; St. Err. Kurt = stan-

dard error of kurtosis.

Exploratory factor analysis (the method of extraction was the Maxi-

mum Likelihood Method, while the selected rotation was Direct Oblim-

in rotation) was also conducted for this construct (see Table 44). Results

have shown that the ratio of standard errors of kurtosis and skewness

range between values of -2 and 2, which implies normality of distribu-

tion.

In the first exploratory factor analysis, we comprised all seven items to

measure product eco-innovation. The appropriateness of factor analysis

was determined by examining the correlation matrix of product eco-in-

novation items. The Bartlett’s test of sphericity showed that the correla-

tion matrix has significant correlations (sig. = 0.000 for all items). Fur-

thermore, the Kaiser-Meyer-Olkin measure of sampling adequacy was

examined and indicated similar results; specifically, the KMO value was

0.856, which indicates an excellent sample adequacy.

N Mean St. Dev. Skew St. Err. Kurt St. Err.

Skew Kurt

The company is using 223 2.59 1.993 0.979 0.163 -0.410 0.324

eco-labeling.

The company chooses 223 4.61 1.789 -0.443 0.163 -0.718 0.324

materials of the product

that consume the least

amount of energy and

resources for conduct-

ing the product develop-

ment or design.

The company uses the

smallest amount of ma-

terials to comprise the 223 4.89 1.786 -0.686 0.163 -0.467 0.324

product for conduct-

180 ing the product develop-

ment or design.

The company deliber- 223 4.50 1.917 -0.391 0.163 -0.972 0.324

ately evaluates whether

the product is easy to re-

cycle, reuse and decom-

pose for conducting the

product development

or design.

Note: N = number of observations; Mean = mean value on the Likert scale, which ranges

from 1 to 7 (1 = strongly disagree, 7 = strongly agree); St. Dev. = standard deviation; Skew =

skewness; St. Err. of Skew = standard error of skewness; Kurt = kurtosis; St. Err. Kurt = stan-

dard error of kurtosis.

Exploratory factor analysis (the method of extraction was the Maxi-

mum Likelihood Method, while the selected rotation was Direct Oblim-

in rotation) was also conducted for this construct (see Table 44). Results

have shown that the ratio of standard errors of kurtosis and skewness

range between values of -2 and 2, which implies normality of distribu-

tion.

In the first exploratory factor analysis, we comprised all seven items to

measure product eco-innovation. The appropriateness of factor analysis

was determined by examining the correlation matrix of product eco-in-

novation items. The Bartlett’s test of sphericity showed that the correla-

tion matrix has significant correlations (sig. = 0.000 for all items). Fur-

thermore, the Kaiser-Meyer-Olkin measure of sampling adequacy was

examined and indicated similar results; specifically, the KMO value was

0.856, which indicates an excellent sample adequacy.