Page 184 - Hojnik, Jana. 2017. In Persuit of Eco-innovation. Drivers and Consequences of Eco-innovation at Firm Level. Koper: University of Primorska Press

P. 184

In Pursuit of Eco-innovation

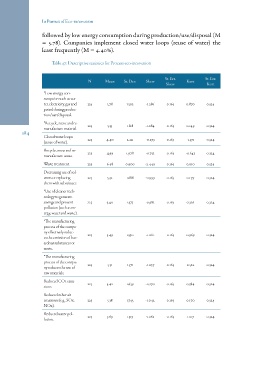

followed by low energy consumption during production/use/disposal (M

= 5.78). Companies implement closed water loops (reuse of water) the

least frequently (M = 4.40%).

Table 47: Descriptive statistics for Process eco-innovation

N Mean St. Dev. Skew St. Err. Kurt St. Err.

Skew Kurt

*Low energy con-

sumption such as wa-

ter, electricity, gas and 223 5.78 1.502 -1.286 0.163 0.870 0.324

petrol during produc-

tion/use/disposal.

184 *Recycle, reuse and re- 223 5.33 1.818 -1.084 0.163 0.149 0.324

manufacture material. 223 4.40 2.211 -0.273 0.163 -1.371 0.324

Closed water loops

(reuse of water).

Recycle, reuse and re- 223 4.99 1.978 -0.752 0.163 -0.643 0.324

manufacture waste.

Waste treatment. 223 6.48 0.900 -2.449 0.163 0.010 0.324

Decreasing use of sol- 223 5.32 1.688 -0.999 0.163 0.179 0.324

vents or replacing

them with substitutes.

*Use of cleaner tech-

nology to generate

savings and prevent 223 5.40 1.573 -0.982 0.163 0.326 0.324

pollution (such as en-

ergy, water and waste).

*The manufacturing

process of the compa-

ny effectively reduc- 223 5.49 1.530 -1.160 0.163 0.969 0.324

es the emission of haz-

ardous substances or

waste.

*The manufacturing

process of the compa- 223 5.31 1.571 -1.037 0.163 0.522 0.324

ny reduces the use of

raw materials.

Reduced CO2 emis- 223 5.42 1.639 -1.070 0.163 0.384 0.324

sions.

Reduced other air 223 5.38 1.743 -1.042 0.163 0.170 0.324

emissions (e.g., SOx,

NOx).

Reduced water pol- 223 5.69 1.519 -1.262 0.163 1.107 0.324

lution.

followed by low energy consumption during production/use/disposal (M

= 5.78). Companies implement closed water loops (reuse of water) the

least frequently (M = 4.40%).

Table 47: Descriptive statistics for Process eco-innovation

N Mean St. Dev. Skew St. Err. Kurt St. Err.

Skew Kurt

*Low energy con-

sumption such as wa-

ter, electricity, gas and 223 5.78 1.502 -1.286 0.163 0.870 0.324

petrol during produc-

tion/use/disposal.

184 *Recycle, reuse and re- 223 5.33 1.818 -1.084 0.163 0.149 0.324

manufacture material. 223 4.40 2.211 -0.273 0.163 -1.371 0.324

Closed water loops

(reuse of water).

Recycle, reuse and re- 223 4.99 1.978 -0.752 0.163 -0.643 0.324

manufacture waste.

Waste treatment. 223 6.48 0.900 -2.449 0.163 0.010 0.324

Decreasing use of sol- 223 5.32 1.688 -0.999 0.163 0.179 0.324

vents or replacing

them with substitutes.

*Use of cleaner tech-

nology to generate

savings and prevent 223 5.40 1.573 -0.982 0.163 0.326 0.324

pollution (such as en-

ergy, water and waste).

*The manufacturing

process of the compa-

ny effectively reduc- 223 5.49 1.530 -1.160 0.163 0.969 0.324

es the emission of haz-

ardous substances or

waste.

*The manufacturing

process of the compa- 223 5.31 1.571 -1.037 0.163 0.522 0.324

ny reduces the use of

raw materials.

Reduced CO2 emis- 223 5.42 1.639 -1.070 0.163 0.384 0.324

sions.

Reduced other air 223 5.38 1.743 -1.042 0.163 0.170 0.324

emissions (e.g., SOx,

NOx).

Reduced water pol- 223 5.69 1.519 -1.262 0.163 1.107 0.324

lution.